Carring on our journey through natural and sustainable fibers, today we will discover the SeaCell fiber.

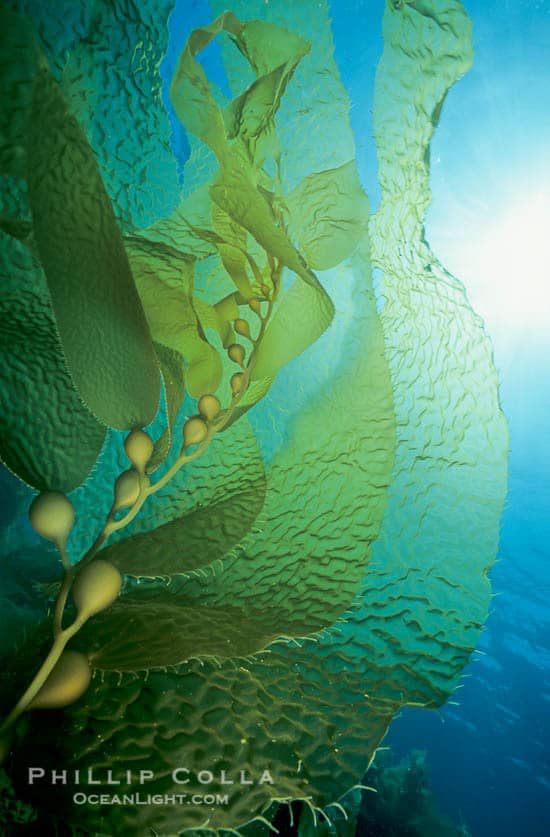

Even those who have never heard of this fiber will have by now guessed what is the natural element it comes from by seeing the images at the head of this article, the SeaCell fiber derives indeed from marine algae.

It is a totally natural fiber, obtained from processing a specific type of algae named Ascophyllum Nodosum seaweed, better known as kelp seaweed, present in the seas of northern Europe and near the coasts of Iceland.

Ascophyllum Nodosum is an important source of protective substances: alginates with a detoxifying effect, iodine, amino acids, antioxidants, A-C-E vitamins, beta-carotene, polyphenols and minerals, calcium, potassium, magnesium and selenium.

The collection of algae is a delicate and selective process but, above all, it is a sustainble kind or harvest and with a low environmental impact. In fact, by removing only the part of the algae that is able to regenerate itself, the ecosystem has the possibility to maintain a natural life process.

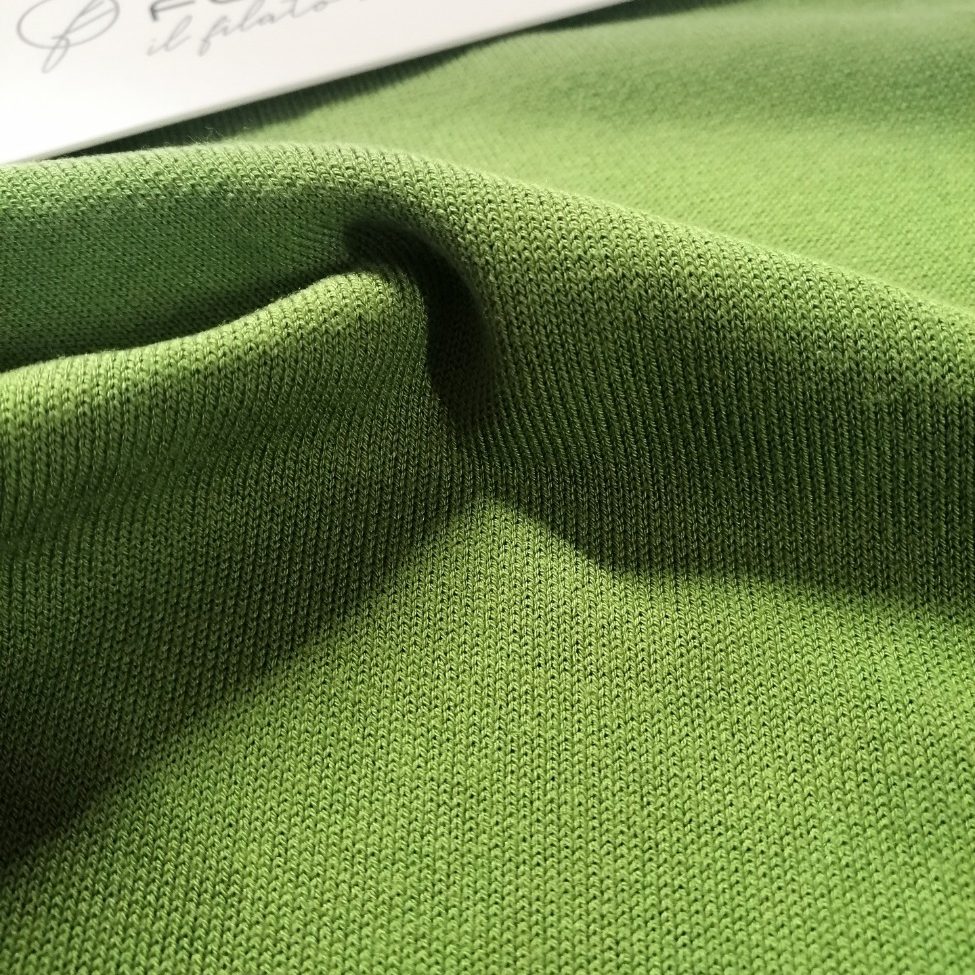

Regarding the structure of the fiber, it is porous and gives the yarns optimal hygroscopic characteristics. The seaweed fiber absorbs the excess moisture, while the skin absorbs the healthy elements it releases, giving the body a comfortable feeling of well-being and freshness.

The natural anti-inflammatory, anti-itching and filtering properties of Seacell fiber make it particularly suitable for skin diseases, to be used almost as a kind of therapeutic form against psoriasis and neurodermatitis.

The Smartfiber AG company holds the Seacell patent, after years and years of study and research they have developed different types of yarns that contain different percentages of Seacell fiber.

These include SeaCellTMLT, a yarn produced exclusively from natural raw materials, cellulose (lyocell) and algae, using innovative methods aimed at a greater sustainability such as saving energy and resources and thanks to the use of only natural vegetable fibers making the yarn completely biodegradable.

The Smartfiber manufacturing process indeed incorporates the algae into a cellulose fiber, as a result, the positive properties of the algae are permanently preserved within the fiber, even after multiple washing cycles.

This innovative and ecological manufacturing process leads to the production of the yarn in a closed cycle without the use of chemicals.

For this the European Union has awarded the Lyocell procedure created by Lenzing the European Environmental Award 2000 in the category “technology for sustainable development”.

As for the world of knitwear concern, one of the spinning mills we work with that has chosen to include a yarn made with Seacell fiber in its collection is the Olcese Ferrari spinning mill. The yarn is called Kelp is composed of 70% viscose bamboo, another sustainable fiber that we have discussed in a previous article and 30% of Seacell.

Curiosity: A series of products such as plant fertilizers and many face and body creams derive from the Ascophyllum Nodosum seaweed.

From the Kosmeticanews.it website:

“Ascophyllum nodosum algae applied to the skin with appropriate massages and drainage, are able to activate the draining, anti-inflammatory and anti-edematous properties by donating to the epidermis the active ingredients, the micro- and meso-elements and biologically active compounds of this miraculous alga, in in such a way as to reactivate subcutaneous blood and lymphatic microcirculation and stimulate cellular metabolism, thus helping to eliminate accumulated and excess toxins so as to carry out a reducing, detoxifying and oxygenating action. “

Sources for this article:

https://www.smartfiber.de/en/seacell-fiber/

http://www.filatimaclodio.it/filatimaclodio/seacell/

https://www.econote.it/2016/06/16/alghemoda/

https://www.smartfiber.de/en/seacell-fiber/

https://bigbloomhydro.wordpress.com/tag/ascophyllum-nodosum/

https://www.kosmeticanews.it/ascophyllum-nodosum-contro-cellulite-e-invecchiamento/

Credits Philip Colla seaweed images: https://www.oceanlight.com/spotlight.php?img=00627